Getting the torque specs right is critical when installing an intake manifold on a Small Block Chevy, especially the classic Chevy 350 (5.7L V8). Overtightening can crack aluminum castings, while undertightening leads to vacuum leaks and oil consumption.

Whether you are installing a stock replacement or upgrading to a Performance Manifold, this guide covers the exact specs, tightening sequence, and installation tips you need.

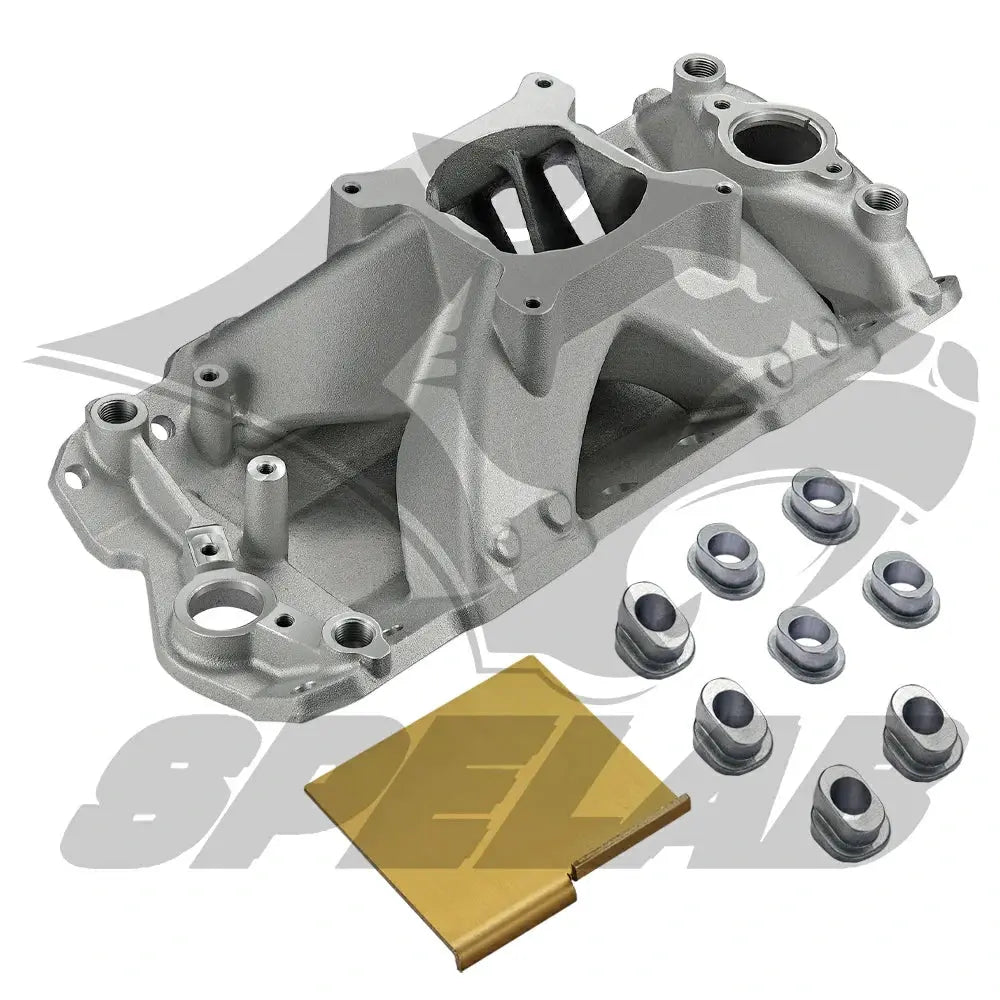

Quick Answer: Chevy 350 Torque Specs

| Manifold Material | Torque Specification | Application Notes |

|---|---|---|

| Cast Iron (OEM) | 30 ft-lbs | Standard for older stock engines. |

| Aluminum (Aftermarket) | 20–25 ft-lbs | Recommended for SPELAB Manifolds on Chevy 350. Do not exceed to prevent cracking the aluminum ears. |

| Bolt Size | 3/8"-16 | Standard SBC bolt thread pitch. |

12-Bolt Tightening Sequence (Center-out)

Why center‑out?

Tightening from the middle outward flattens the gasket evenly, prevents manifold warp, and avoids lifted corners that cause vacuum leaks or coolant leaks.

Torque passes

- Pass 1: Snug / 8–10 ft-lbs

- Pass 2: 15–18 ft-lbs

- Pass 3: Final torque (see table above)

Upgrade Your Chevy 350: Single Plane vs. Dual Plane

Since you are installing a new intake, make sure you choose the right performance profile. Are you building a street cruiser or a high-RPM racer? Here is the difference:

Dual-Plane Intake for Chevy 350

RPM Range: Idle - 5,500 RPM

Optimized for the Chevy 350 (5.7L). This 180° design boosts low-end torque and throttle response, making it the perfect upgrade for daily drivers, trucks, and stock engines.

Shop 350 Dual-Plane >

High-Rise Single-Plane for Chevy 350

RPM Range: 3,000 - 7,500+ RPM

Designed for modified SBC 350 engines. Features a large open plenum for maximum airflow at high RPMs. Ideal for drag racing and engines with high-lift cams.

Shop 350 Single-Plane >Step-by-Step Installation Tips

- Clean the Surfaces: Ensure the cylinder head mating surfaces are spotless. Remove all old gasket material.

-

Throw Away the End Seals: The cork rubber seals for the front and rear engine block rails (China Walls) are prone to leaking.

Pro Tip: Use a thick bead (1/4 inch) of RTV Silicone instead of the cork gaskets. - Use Thread Sealant: The four center bolts on a Chevy 350 often go into the water jacket/lifter valley. Apply PTFE thread sealer to prevent oil creeping up the threads or coolant leaks.

-

The 3-Pass Method: Do not tighten to 25 ft-lbs immediately.

- Pass 1: Snug all bolts to 10 ft-lbs following the sequence.

- Pass 2: Tighten to 18 ft-lbs following the sequence.

- Pass 3: Finish at 20-25 ft-lbs.

Frequently Asked Questions (FAQ)

Q: Do I need to re-torque the intake manifold bolts on my Chevy 350?

A: Yes. Aluminum intake manifolds expand and contract differently than the cast iron heads found on most Chevy 350s. We recommend re-torquing the bolts after the engine has gone through one full heat cycle (reached operating temp and cooled down completely).

Q: Why choose Aluminum over Cast Iron for a Chevy 350?

A: Weight and Heat. A Aluminum Manifold saves about 15-20 lbs off the front end of your car. Aluminum also dissipates heat faster, keeping the intake charge cooler for better power.

Q: Will these manifolds fit my Vortec 350 heads?

A: No. These specific manifolds fit 1955-1986 SBC cylinder heads (Pre-Vortec) with the traditional 12-bolt pattern. 1996+ Chevy 350 Vortec heads use a different 8-bolt pattern.

Q: Can I use a stock carburetor with these manifolds?

A: SPELAB manifolds feature a standard 4150 Square Bore flange. If your Chevy 350 has a stock Quadrajet (Spread Bore), you will need a simple adapter plate.