Unlock the full potential of your Ford Super Duty with the right intercooler upgrade. Intercoolers are essential for enhancing engine performance, reducing turbo stress, and improving fuel efficiency. In this guide, we explore the best intercooler options, compare air-to-air and water-to-air designs, and offer expert advice on installation and maintenance. Whether you're aiming for better power output or increased reliability, understanding how intercoolers work and selecting the right one can make a significant difference in your vehicle’s performance.

1. The Importance of Upgrading Your Intercooler for Ford Super Duty Performance

Upgrading your intercooler is crucial for maximizing the performance of your Ford Super Duty, particularly the 2003-2007 models with the 6.0L Powerstroke engine. An effective intercooler, such as a front mount intercooler or an air to water intercooler, reduces the temperature of the compressed air from the turbocharger, enhancing engine efficiency and power output. This section will explore why these intercoolers are vital for your vehicle's performance.

1.1 Why Choose a Front Mount Intercooler?

1.1.1 Advantages of Front Mount Intercoolers

Front mount intercoolers (FMIC) are preferred for their superior cooling capabilities. Positioned at the front of the vehicle, they benefit from maximum airflow, which is crucial for effective heat dissipation. This setup is especially advantageous for high-performance and modified vehicles, as it helps maintain lower intake temperatures, leading to better combustion and increased power.

- Enhanced Cooling: Front mount intercoolers receive the most airflow, ensuring optimal cooling performance.

- Reduced Turbo Lag: By keeping intake temperatures low, front mount intercoolers minimize turbo lag, resulting in a more immediate throttle response.

- Improved Engine Durability: Lower intake temperatures reduce the risk of detonation and excessive wear, thereby extending engine life.

1.1.2 Specific Performance Enhancements for Ford Super Duty

Installing a front mount intercooler in your Ford Super Duty can lead to significant performance improvements, especially under heavy load or in hot climates. The improved cooling capacity ensures that your engine remains efficient, even in extreme conditions, offering benefits such as:

- Increased Towing Capacity: With a cooler and more efficient engine, your vehicle can handle heavier loads without compromising performance.

- Enhanced Throttle Response: Reduced turbo lag results in quicker acceleration and better overall drivability.

- Extended Engine Life: Consistent lower intake temperatures help in maintaining the engine's integrity over time, reducing maintenance costs.

1.2 Advantages of Air to Water Intercoolers

Air to water intercooler offer unique benefits, particularly for extreme performance applications. Unlike traditional air to air intercoolers, these systems use water as a cooling medium, which can absorb heat more efficiently.

1.2.1 How Air to Water Intercoolers Enhance Engine Efficiency

- Efficient Heat Exchange: Water's higher thermal conductivity allows for more effective heat removal from the compressed air, keeping intake temperatures lower.

- Compact Design: These intercoolers can be smaller and more versatile in terms of installation, making them suitable for vehicles with limited front-end space.

- Consistent Performance: Regardless of external air temperatures, air to water intercoolers provide consistent cooling performance, which is crucial for maintaining engine efficiency.

1.2.2 Ideal Scenarios for Air to Water Intercoolers

- Extreme Performance: For vehicles pushing the limits of performance, such as racing applications, air to water intercoolers provide the necessary cooling efficiency to prevent overheating.

- Limited Space: In scenarios where space constraints prevent the installation of a large front mount intercooler, air to water intercoolers offer a compact and efficient alternative.

- High Ambient Temperatures: In regions with consistently high temperatures, the effectiveness of air to air intercoolers might be compromised. Air to water systems ensure stable performance regardless of ambient conditions.

Now that you understand the critical role of front mount and air to water intercoolers in enhancing the performance of your Ford Super Duty, let's delve into the types of intercoolers available. Continue reading to discover which type suits your needs best.

2. Comparing Intercooler Types for Ford Super Duty

Choosing the right intercooler for your Ford Super Duty involves understanding the differences between water to air and air to air intercoolers. Each type has its advantages and ideal use cases, which we'll explore in this section.

2.1 Water to Air Intercoolers (WTA)

2.1.1 Working Principle

Water to air intercoolers use water as a medium to transfer heat away from the compressed air. This type of intercooler has a heat exchanger that allows the heated air to pass through, where it is cooled by water circulating through a separate system.

- Heat Exchange: The hot compressed air from the turbocharger passes through the intercooler's core, where water absorbs the heat.

- Cooling System: The heated water is then pumped through a radiator or heat exchanger, where it releases the heat into the atmosphere, before being recirculated to continue the cooling process.

2.1.2 Pros and Cons

Pros:

- Superior Cooling Efficiency: Water's high thermal conductivity ensures effective heat transfer, resulting in lower intake temperatures.

- Compact Design: Suitable for installations where space is limited, offering flexibility in placement.

- Consistent Performance: Effective even in high ambient temperatures, providing reliable cooling regardless of external conditions.

Cons:

- Complexity: Requires a more complex setup, including a pump, water reservoir, and additional plumbing.

- Maintenance: Potential for leaks and the need for regular maintenance to ensure the system remains effective.

2.2 Air to Air Intercoolers (ATA)

2.2.1 Working Principle

Air to air intercoolers rely on the vehicle's movement to pass ambient air over the intercooler's core, cooling the compressed air from the turbocharger. This type is more straightforward in design and operation.

- Heat Exchange: The hot compressed air passes through the intercooler's core, where it is cooled by the external air flowing over the fins.

- Natural Cooling: Utilizes the vehicle's forward motion to drive air through the intercooler, requiring no additional components like pumps or reservoirs.

2.2.2 Pros and Cons

Pros:

- Simplicity: Easier to install and maintain, with fewer components and less complexity.

- Cost-Effective: Generally less expensive than water to air systems due to the simpler design.

- Reliability: Fewer parts mean there is less that can go wrong, leading to increased reliability.

Cons:

- Cooling Efficiency: Less effective in high ambient temperatures or when the vehicle is stationary, as it relies on airflow for cooling.

- Space Requirements: Typically larger and may require more space for installation, limiting placement options.

Now that you have a clear understanding of the differences between water to air and air to air intercoolers, let's move on to the next crucial step. Read on to learn how to choose the right intercooler for your specific needs.

3. How to Choose the Right Intercooler for Your Needs

Selecting the appropriate intercooler for your Ford Super Duty involves considering various factors, including your performance goals and vehicle specifications. In this section, we will discuss how to evaluate your needs and match the right intercooler to your vehicle.

3.1 Evaluating Your Needs

3.1.1 Performance vs. Daily Driving

Before choosing an intercooler, determine whether your focus is on maximizing performance or improving daily driving efficiency. Performance-oriented setups may require more advanced intercoolers, like air to water systems, while daily drivers might benefit more from simpler air to air intercoolers.

- Performance Needs: If you are aiming for significant performance gains, such as those needed for racing or heavy-duty towing, a high-efficiency intercooler that can handle increased airflow and boost levels is essential.

- Daily Driving: For everyday use, a reliable and easy-to-maintain intercooler that enhances fuel efficiency and provides consistent performance is ideal.

3.1.2 Modification Level

Consider the extent of your vehicle modifications. Heavily modified engines may benefit from more advanced cooling solutions, while stock or lightly modified engines might not require such intensive upgrades.

- Heavily Modified Vehicles: These vehicles can push intercoolers to their limits, so choosing a high-capacity, robust intercooler is crucial.

- Stock or Lightly Modified Vehicles: A standard air to air intercooler might be sufficient to handle the thermal loads generated by these engines.

3.2 Matching the Intercooler to Your Vehicle

3.2.1 Ford Super Duty Series

Ensure that the intercooler you choose is compatible with your specific model of Ford Super Duty. Different models and years might have variations in engine bay design, which can affect the fitment of the intercooler.

- 2003-2007 Ford Super Duty: This guide specifically addresses the 6.0L Powerstroke engine in the 2003-2007 Ford F-250, F-350, F-450, and F-550 Super Duty models. Verify that the intercooler is designed to fit these vehicles.

- Ford Excursion: If you own a Ford Excursion with the 6.0L Powerstroke engine, ensure the intercooler is also compatible with this model.

3.2.2 Various Modification Levels

Depending on your vehicle's modifications, you may need a specific type of intercooler. High-performance setups might require more robust intercoolers that can handle increased boost pressures and airflow.

- Turbocharged Setups: Vehicles with twin turbo setups or other high-boost configurations require intercoolers that can manage higher heat loads and pressure levels.

- Naturally Aspirated Engines: While less common, if your setup involves a naturally aspirated engine, an air to air intercooler might still provide benefits by cooling the intake charge.

With a clear understanding of how to evaluate your needs and match the right intercooler to your vehicle, you are ready to move forward. Next, we'll explore the ease of installation for front mount intercoolers in Ford Super Duty models. Continue reading to learn more.

4. Ease of Installation for Front Mount Intercoolers in Ford Super Duty Models

Installing a front mount intercooler in your Ford Super Duty can be a straightforward process, especially if you choose an intercooler designed for a bolt-on installation. This section will cover the steps involved and provide tips for a smooth installation.

4.1 Preparing for Installation

4.1.1 Tools and Equipment

Before you begin, gather all necessary tools and equipment. This typically includes basic hand tools, a jack and jack stands, and potentially some specialty tools depending on your vehicle's setup.

- Basic Hand Tools: Wrenches, screwdrivers, pliers, and sockets.

- Specialty Tools: Depending on your vehicle, you might need specific tools like a torque wrench or intercooler pipe removal tools.

- Safety Equipment: Always use appropriate safety gear, such as gloves and safety glasses.

4.1.2 Preparation Steps

Ensure your vehicle is safely supported on jack stands and that you have clear access to the intercooler area. Disconnect the battery to prevent any electrical issues during the installation.

- Lift the Vehicle: Use a jack to lift the front of the vehicle and place it securely on jack stands.

- Disconnect the Battery: This is an important safety step to prevent any accidental electrical shorts or shocks.

- Remove Obstructions: Take off any components that may obstruct access to the intercooler, such as the front bumper or splash guards.

4.2 Step-by-Step Installation Guide

4.2.1 Removing the Stock Intercooler

Carefully remove the stock intercooler, following the steps outlined below.

- Disconnect Intercooler Pipes: Loosen and remove the clamps connecting the intercooler pipes to the turbocharger and intake manifold.

- Remove Mounting Bolts: Locate and remove the bolts securing the stock intercooler in place.

- Carefully Extract the Intercooler: Gently remove the intercooler from its mounting position, being cautious not to damage any surrounding components.

4.2.2 Installing the New Intercooler

Follow these steps to install your new front mount intercooler.

- Position the Intercooler: Carefully place the new intercooler in the mounting location, ensuring it aligns with the existing mounting points.

- Secure the Intercooler: Use the provided hardware to secure the intercooler in place, tightening the bolts to the manufacturer's specifications.

- Reconnect Intercooler Pipes: Attach the intercooler pipes to the new intercooler, ensuring all clamps are securely tightened to prevent leaks.

- Reassemble Any Removed Components: Replace any parts you removed earlier, such as the front bumper or splash guards.

4.2.3 Final Checks and Testing

Once the new intercooler is installed, perform a series of checks to ensure everything is properly connected and functioning.

- Double-Check Connections: Verify that all clamps and bolts are securely tightened.

- Reattach the Battery: Reconnect the battery and start the engine, checking for any air leaks or unusual sounds.

- Test Drive: Take your vehicle for a test drive to ensure the intercooler is functioning correctly and there are no issues with boost pressure or engine performance.

With your front mount intercooler successfully installed, you're ready to experience the performance benefits. Next, we'll discuss how to maintain your intercooler to ensure it continues to perform optimally. Continue reading to learn about intercooler maintenance and care.

5. Analyzing the Performance Benefits of Intercoolers

Intercoolers play a crucial role in enhancing engine performance by cooling the intake air, which leads to several key performance improvements. This section will delve into the specific benefits an intercooler can bring to your Ford Super Duty, focusing on how it improves engine efficiency and overall performance.

5.1 Increasing Engine Efficiency

5.1.1 Lowering Intake Temperatures

One of the primary benefits of an intercooler is its ability to lower the temperature of the air entering the engine. Cooler intake air is denser and contains more oxygen, which improves the combustion process.

- Enhanced Combustion: With cooler, denser air, the engine can burn fuel more efficiently, leading to better power output and fuel economy.

- Reduced Engine Knock: Lower intake temperatures decrease the likelihood of engine knock (pre-detonation), which can damage engine components and reduce performance.

5.1.2 Improving Fuel Efficiency

By ensuring that the engine operates at optimal temperatures, an intercooler can help improve fuel efficiency.

- Optimized Air-Fuel Ratio: Cooler air allows for a better air-fuel mixture, leading to more complete combustion and improved fuel efficiency.

- Decreased Exhaust Temperatures: Lower intake temperatures reduce the strain on the engine, which can decrease exhaust temperatures and improve overall engine efficiency.

5.2 Increasing Horsepower and Torque

5.2.1 Actual Performance Gains

Installing a high-quality intercooler can result in a noticeable increase in horsepower and torque. This is especially true for vehicles with modified engines or those used for towing and heavy-duty applications.

- Power Output: Cooler intake air enables the engine to produce more power by increasing the volume of air that can be effectively burned.

- Torque Improvement: Enhanced air density and combustion efficiency translate into higher torque, which improves acceleration and towing capacity.

5.2.2 Enhanced Driving Experience

The performance gains provided by an intercooler translate into a more responsive and enjoyable driving experience.

- Better Acceleration: Increased horsepower and torque contribute to quicker acceleration and improved throttle response.

- Enhanced Towing Capability: Higher torque and cooler intake temperatures make towing heavy loads easier and more efficient.

With a clear understanding of how an intercooler enhances engine efficiency and performance, you’re now ready to explore the materials and design features of intercoolers. Continue reading to discover the benefits of various intercooler designs and materials.

6. Understanding Intercooler Materials and Design Features

The effectiveness of an intercooler is significantly influenced by the materials used in its construction and its overall design. This section will explore the key materials and design features that impact intercooler performance and durability.

6.1 Common Intercooler Materials

6.1.1 Aluminum vs. Plastic

The materials used in intercooler construction affect both performance and longevity.

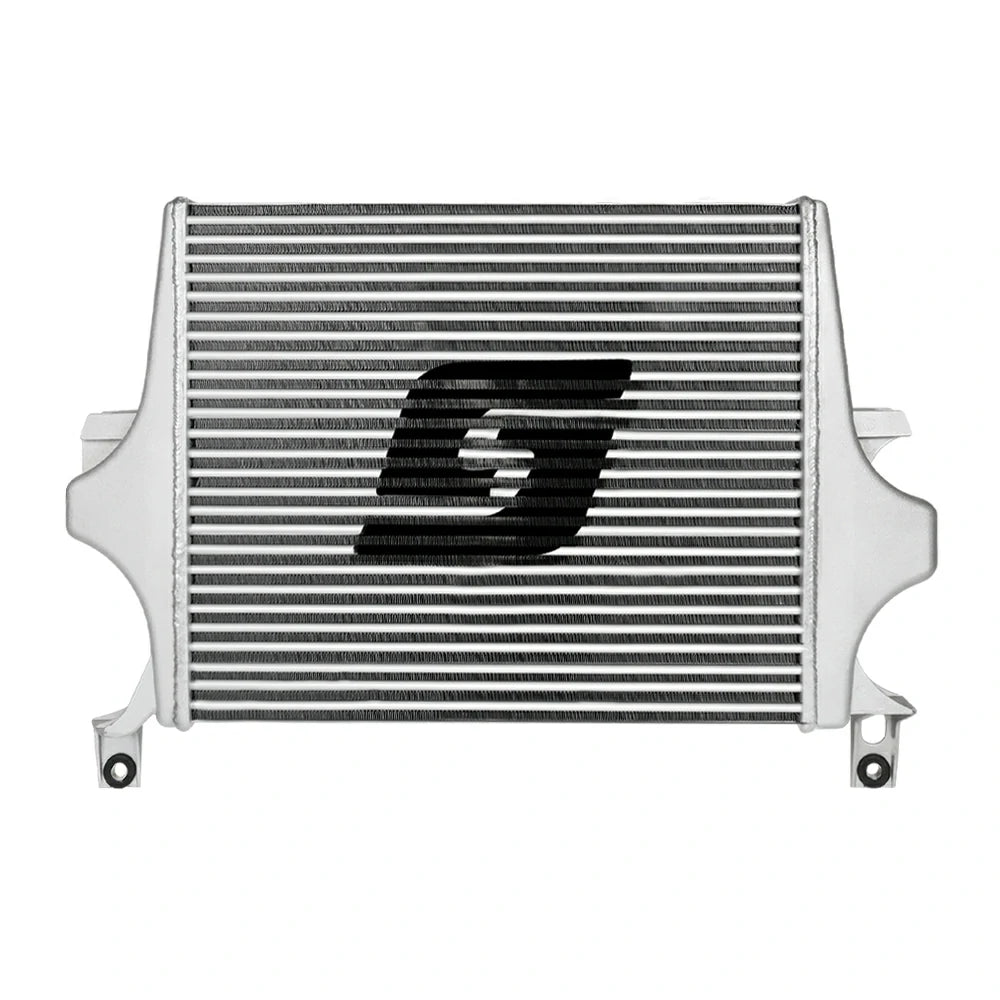

Aluminum: Most high-performance intercoolers use aluminum due to its excellent heat dissipation properties and durability. Aluminum intercoolers typically feature cast-aluminum end tanks and tube-and-fin cores, providing a balance of weight, strength, and cooling efficiency.

- Durability: Cast-aluminum end tanks resist cracking and can handle higher pressure, making them suitable for modified engines and extreme conditions.

- Heat Dissipation: Aluminum's superior thermal conductivity ensures effective heat transfer from the intake air to the ambient air.

Plastic: Some stock or less performance-oriented intercoolers use plastic end tanks. While cheaper and lighter, plastic tanks are generally less durable and can crack under higher pressures or extreme temperatures.

- Cost: Plastic end tanks reduce manufacturing costs, making them more economical for stock applications.

- Temperature Limitations: Plastic may not perform as well under high temperatures or with higher boost pressures.

6.1.2 Tube-and-Fin vs. Bar-and-Plate Cores

The core design of the intercooler plays a critical role in its cooling efficiency.

Tube-and-Fin: This design features a series of tubes with fins attached, which are excellent for lightweight applications and general performance improvements. The increased surface area provided by the fins enhances heat exchange between the intake air and the ambient air.

- Lightweight: Ideal for stock or lightly modified vehicles where weight is a concern.

- Efficient Heat Transfer: Provides good cooling efficiency for standard performance needs.

Bar-and-Plate: This design includes a series of bars and plates stacked together to increase the surface area for heat dissipation. Bar-and-plate cores are typically more robust and suited for high-performance applications.

- High Durability: Suitable for vehicles with high boost levels or extreme driving conditions.

- Superior Cooling: Provides more efficient heat dissipation compared to tube-and-fin designs.

6.2 Design Features That Enhance Performance

6.2.1 Air Diverters and Internal Design

Air Diverters: Some intercoolers feature air diverters within the end tanks to evenly distribute airflow across the core. This design helps improve heat transfer and ensures that the entire surface area of the intercooler is utilized effectively.

- Improved Airflow Distribution: Ensures consistent cooling across the entire intercooler surface.

- Enhanced Efficiency: Helps in reducing hot spots and improves overall cooling performance.

6.2.2 Core Thickness and Size

Core Thickness: The thickness of the intercooler core affects its cooling capacity. Thicker cores generally provide better cooling performance by allowing more time for heat exchange between the air and the cooler.

- Increased Efficiency: Thicker cores can handle higher volumes of air and provide more effective cooling.

- Space Considerations: Ensure that the thickness of the intercooler is compatible with your vehicle's available space.

Size: The size of the intercooler impacts its ability to cool the intake air. Larger intercoolers generally offer better cooling performance but may require more space.

- Higher Cooling Capacity: Larger intercoolers are beneficial for high-performance or heavily modified vehicles.

- Fitment: Ensure that the size of the intercooler is appropriate for your vehicle’s engine bay and cooling requirements.

With a solid understanding of intercooler materials and design features, you’re now equipped to select an intercooler that best suits your performance needs. Next, we'll discuss the impact of intercooler upgrades on vehicle reliability and maintenance. Continue reading to ensure your intercooler upgrade contributes to long-term vehicle health.

7. Impact of Intercooler Upgrades on Vehicle Reliability and Maintenance

Upgrading your intercooler can have significant effects on your vehicle’s reliability and maintenance needs. This section will explore how different types of intercoolers affect long-term vehicle health and what maintenance practices are essential for keeping your intercooler in top condition.

7.1 Enhancing Vehicle Reliability

7.1.1 Improved Engine Longevity

A high-quality intercooler helps in maintaining optimal engine temperatures, which is crucial for engine longevity and overall vehicle reliability.

- Reduced Heat Stress: By cooling the intake air effectively, the intercooler reduces the thermal stress on the engine. Lower temperatures help prevent overheating and reduce the risk of engine damage.

- Consistent Performance: An efficient intercooler maintains stable engine performance by ensuring that the intake air temperature remains consistent, which can reduce the likelihood of performance issues related to heat.

7.1.2 Preventing Common Failures

Upgrading to a more robust intercooler can prevent common failures associated with stock intercoolers.

- Avoiding Cracking: High-performance intercoolers with durable materials like cast aluminum are less prone to cracking compared to stock plastic intercoolers, which can fail under high pressure or temperature.

- Improved Pressure Handling: Upgraded intercoolers are designed to handle higher boost pressures, reducing the risk of failures related to excessive boost levels.

7.2 Maintenance and Care Tips

7.2.1 Regular Inspections

Routine inspections are crucial for ensuring that your intercooler remains in good working condition.

- Check for Leaks: Regularly inspect the intercooler and its connections for signs of leaks. Leaks can compromise the intercooler’s performance and lead to engine problems.

- Inspect Connections and Clamps: Ensure that all intercooler pipes and clamps are secure and free from damage. Loose connections can result in boost leaks and reduced performance.

7.2.2 Cleaning the Intercooler

Over time, intercoolers can accumulate dirt and debris, which can affect their performance. Regular cleaning is necessary to maintain optimal function.

- Cleaning Procedure: Use a mild detergent and water to clean the intercooler’s exterior. For more thorough cleaning, especially if you notice a significant buildup of grime, a specialized intercooler cleaner or solvent can be used.

- Internal Cleaning: If you suspect that the intercooler’s internal passages are clogged, it may be necessary to have it professionally cleaned. This ensures that airflow is not restricted and that cooling efficiency is maintained.

7.2.3 Professional Maintenance

For complex issues or extensive maintenance, consult a professional to ensure that the intercooler is properly serviced and any underlying problems are addressed.

- Professional Inspections: Regular professional inspections can help identify potential issues before they become serious problems. Mechanics can provide a thorough evaluation of the intercooler and related components.

- Timely Repairs: Address any issues identified during inspections promptly to prevent further damage and maintain optimal performance.

With an understanding of how intercooler upgrades can impact vehicle reliability and the best practices for maintenance, you're now well-prepared to keep your vehicle in peak condition. Next, we will wrap up our guide with a summary of key takeaways and a final recommendation on choosing the best intercooler for your Ford Super Duty.

8. Conclusion and Final Recommendations for Choosing the Best Intercooler

In this final section, we summarize the key points covered in the guide and provide recommendations for selecting the best intercooler for your Ford Super Duty. This will help you make an informed decision and ensure that your vehicle receives the optimal performance benefits from your intercooler upgrade.

Fitment:

2003-2007 Ford F-250 Super Duty (6.0L Powerstroke)

2003-2007 Ford F-350 Super Duty (6.0L Powerstroke)

2003-2007 Ford F-450 Super Duty (6.0L Powerstroke)

2003-2007 Ford F-550 Super Duty (6.0L Powerstroke)

2003-2005 Ford Excursion (6.0L Powerstroke)

8.1 Summary of Key Points

8.1.1 Importance of Intercoolers

Intercoolers are essential for enhancing engine performance by cooling the intake air, which improves combustion efficiency, fuel economy, and overall power output. The choice between different types, such as front mount and air to water intercoolers, depends on your performance goals and vehicle usage.

8.1.2 Comparing Intercooler Types

- Water to Air Intercoolers: Provide superior cooling efficiency and are ideal for high-performance applications but require more complex installation and maintenance.

- Air to Air Intercoolers: Simpler and cost-effective, suitable for standard performance needs and easier to maintain.

8.1.3 Installation and Maintenance

Choosing an intercooler that is easy to install and maintain can save time and ensure long-term reliability. Front mount intercoolers offer straightforward installation with bolt-on options, while regular maintenance is crucial for keeping the intercooler and vehicle in top condition.

8.2 Final Recommendations

8.2.1 Choose Based on Your Needs

Select an intercooler that matches your performance requirements and vehicle setup. For heavily modified engines or high-performance applications, a robust air to water intercooler with a high-capacity core is recommended. For stock or lightly modified vehicles, a reliable and cost-effective air to air intercooler may be sufficient.

- Performance Goals: Align the choice of intercooler with your performance goals, whether for daily driving, towing, or high-performance racing.

- Vehicle Compatibility: Ensure that the intercooler fits your Ford Super Duty model and engine configuration to avoid fitment issues and ensure optimal performance.

8.2.2 Consider Quality and Reliability

Invest in a high-quality intercooler from reputable brands known for durability and performance. Look for features such as durable materials, efficient core designs, and reliable customer support.

- Brand Reputation: Choose intercoolers from trusted manufacturers with positive reviews and proven performance.

- Warranty and Support: Consider products with a warranty and customer support to address any issues or concerns.

8.2.3 Professional Installation and Maintenance

For the best results, consider professional installation and regular maintenance to maximize the benefits of your intercooler upgrade and ensure long-term vehicle health.

- Professional Installation: Ensure that the intercooler is installed correctly to avoid performance issues and potential damage.

- Routine Maintenance: Follow best practices for maintaining the intercooler and vehicle to keep everything running smoothly.

With these insights and recommendations, you are now equipped to select and install the best intercooler for your Ford Super Duty. For personalized advice or to explore top-quality intercooler options, consult with automotive performance specialists or visit our recommended product listings.

FAQs

Q1: Are water to air intercoolers better?

A1: Water to air intercoolers can provide superior cooling efficiency compared to air to air intercoolers. They use water to absorb and dissipate heat from the intake air, which can be more effective in reducing intake temperatures, especially in high-performance or racing applications.

Q2: How does the air-to-water intercooler work?

A2: An air-to-water intercooler uses a heat exchanger to transfer heat from the intake air to a water reservoir. The cooled water then circulates through a separate heat exchanger to release the absorbed heat into the atmosphere, helping to lower the intake air temperature.

Q3: Are intercoolers filled with water?

A3: Not all intercoolers are filled with water. Air-to-air intercoolers use air to cool the intake air, while water-to-air intercoolers use water or a water-coolant mixture to absorb and transfer heat from the intake air.

Q4: How much HP does an intercooler add?

A4: The horsepower gain from an intercooler can vary depending on the vehicle and intercooler type. Typically, an intercooler helps improve engine efficiency by lowering intake temperatures, which can result in a performance increase of approximately 10-30 horsepower, depending on your setup.

Q5: What fluid runs through an intercooler?

A5: In air-to-air intercoolers, there is no fluid running through the intercooler itself—only air. In water-to-air intercoolers, a water or water-coolant mixture runs through the intercooler to absorb heat from the intake air, which is then released through an external heat exchanger.

Q6: What are the benefits of a front mount intercooler?

A6: A front mount intercooler offers several benefits, including enhanced cooling efficiency due to its exposure to cooler ambient air. It allows for a more direct airflow path, which improves heat dissipation and can enhance overall engine performance.

Q7: Can I install a larger intercooler on my vehicle?

A7: Yes, installing a larger intercooler can improve cooling performance and support higher power levels. However, ensure that the larger intercooler fits your vehicle’s engine bay and does not interfere with other components. Some modifications may be necessary for proper installation.

Q8: How often should I clean my intercooler?

A8: Intercooler cleaning frequency depends on your driving conditions. For most vehicles, a thorough cleaning every 6-12 months is recommended, especially if you drive in dusty or off-road conditions. Regular inspections for dirt and debris buildup are also advisable.

Q9: How does a front mount intercooler affect my vehicle’s cooling system?

A9: A front mount intercooler enhances the vehicle’s cooling system by improving the heat dissipation from the intake air. It provides increased airflow to the intercooler core, which helps in maintaining lower intake temperatures and reduces engine strain.

Q10: Do intercoolers require regular maintenance?

A10: Yes, intercoolers require regular maintenance to ensure optimal performance. This includes inspecting for leaks, checking connections, and cleaning the intercooler to remove debris and buildup. Regular maintenance helps to prolong the lifespan of the intercooler and maintain engine efficiency.