Discover how to test and improve intercooler efficiency with Revive. Learn tips for air-to-water, water-to-air, and twin turbo intercoolers.

1. Introduction

The Importance of Intercoolers in Modern Vehicles

Intercoolers play a crucial role in enhancing the performance of turbocharged and supercharged engines. By cooling the compressed air before it enters the engine, intercoolers help increase engine efficiency and power output. Whether you are using an air to water intercooler or a water to air intercooler, the primary goal remains the same: to lower the intake air temperature and improve overall engine performance.

For many performance enthusiasts, especially those involved with front mount intercoolers or twin turbo intercoolers, understanding how well their intercooler is performing can make a significant difference in driving experience and vehicle efficiency. In this article, we’ll explore how to test intercooler efficiency before and after using the Revive cleaning product, providing you with valuable insights into improving your vehicle’s cooling system.

Objective of the Test

The objective of this article is to offer a detailed examination of how effectively the Revive cleaning product enhances intercooler performance. By comparing intercooler efficiency before and after application, you can gain a clearer understanding of the benefits of regular maintenance and the impact of cleaning products on your cooling system.

Next, let’s delve into the basics of intercoolers and their importance.

2. Basics of Intercoolers

What is an Intercooler?

An intercooler is a vital component in turbocharged and supercharged engines, designed to cool the compressed air from the turbocharger or supercharger before it enters the engine’s combustion chamber. This cooling process is crucial because compressed air from these devices is significantly hotter than the ambient air, which can lead to decreased engine performance and efficiency.

Why Intercooler Efficiency Matters

Efficient intercooling is key to achieving optimal engine performance. By reducing the intake air temperature, intercoolers help:

- Improve Engine Power: Cooler air is denser, allowing the engine to burn more fuel and generate more power.

- Reduce Engine Knock: Lower air temperatures help prevent pre-detonation, which can cause engine knock and reduce performance.

- Enhance Turbocharger Longevity: Effective cooling reduces the strain on the turbocharger, potentially extending its lifespan.

Now that you understand the basics of intercoolers, let’s move on to how to test intercooler efficiency.

Related article:https://www.spelabautoparts.com/blogs/news/best-intercoolers-for-ford-super-duty-enhance-performance-reliability

3. Testing Intercooler Efficiency

Overview of Testing Methods

To evaluate the efficiency of your intercooler, especially before and after using a cleaning product like Revive, a structured testing method is crucial. The primary goal of these tests is to measure the temperature differential between the intake and the output of the intercooler, which directly indicates its cooling effectiveness.

Testing Setup

Equipment and Tools

- Temperature Probes: Essential for measuring the air temperature at the inlet and outlet of the intercooler.

- Hair Dryer or Heat Source: Used to simulate engine heat and airflow through the intercooler.

- Fan or Airflow Device: To mimic real driving conditions and ensure consistent airflow through the intercooler.

- Multimeter: For recording temperature data accurately.

Testing Procedure

- Initial Temperature Measurement: Record the temperature of the air entering the intercooler and the temperature of the air exiting it under normal operating conditions.

- Apply Heat Source: Use a hair dryer or similar device to increase the temperature of the air entering the intercooler. Ensure the airflow mimics real engine conditions as closely as possible.

- Record Temperature Changes: Measure and record the temperatures at the intercooler inlet and outlet periodically. This helps determine how effectively the intercooler is cooling the compressed air.

Case Study: Testing Before and After Using Revive

Before Using Revive

- Initial Conditions: Note the ambient temperature and baseline temperatures of the intake and outlet air.

- Results: For instance, you might find that the intercooler outlet temperature is significantly higher than desired, indicating that it is not performing at its best.

After Using Revive

- Cleaning Process: Apply Revive to clean the intercooler, following the manufacturer's instructions carefully.

- Post-Cleaning Test: Repeat the temperature measurements under the same conditions. Compare these results with the pre-cleaning data to assess improvements in efficiency.

Analyzing the Results

- Temperature Differential: Calculate the temperature difference before and after using Revive. A significant reduction in temperature indicates improved intercooler efficiency.

- Effectiveness of Cleaning: Evaluate how much the cleaning process has improved the intercooler’s performance. Consider both the temperature reduction and any changes in performance characteristics.

With a solid understanding of how to test intercooler efficiency, let’s explore the analysis of the test results and discuss the implications.

Reference Video:https://youtu.be/QlABJr2ZZ1g?feature=shared

4. Analyzing Test Results and Implications

Interpreting Temperature Data

Before and After Comparison

When analyzing the temperature data before and after using Revive, the key metrics to focus on are:

- Temperature Drop: Compare the temperature of the air entering and exiting the intercooler before and after cleaning. A larger temperature drop indicates improved cooling efficiency.

- Efficiency Improvement: Assess how much the cleaning product has enhanced the intercooler’s performance. For example, if the outlet temperature decreased significantly after using Revive, it shows that the intercooler is now more effective at cooling the intake air.

Practical Impact on Vehicle Performance

- Power Gains: Improved intercooler efficiency typically results in increased engine power. Cooler intake air can lead to better combustion, higher horsepower, and overall improved performance.

- Reduced Engine Knock: Lower intake temperatures help prevent pre-detonation, which reduces engine knock and improves reliability.

- Turbocharger Longevity: With better cooling, the turbocharger experiences less stress, potentially extending its lifespan and maintaining performance over time.

Implications of Test Results

Enhanced Efficiency and Performance

- For Stock Vehicles: Even on a stock vehicle, improved intercooler efficiency can lead to noticeable performance gains, such as better throttle response and increased horsepower.

- For Modified Vehicles: For those with modified engines or higher boost levels, a more efficient intercooler can significantly enhance performance by providing cooler, denser air for combustion.

Maintenance and Upgrades

- Regular Cleaning: Regular maintenance with cleaning products like Revive can help maintain optimal intercooler performance, preventing efficiency loss due to accumulated debris and oil.

- Upgrading Intercoolers: If testing reveals that the current intercooler is not performing well even after cleaning, consider upgrading to a higher-performance unit. Options like front mount intercoolersor twin turbo intercoolers may offer better cooling capabilities.

Real-World Testing vs. Theoretical Models

- Importance of Real-World Data: As highlighted in the testing methodology, real-world conditions often differ from theoretical models or bench tests. In-road testing provides a more accurate assessment of intercooler performance under actual driving conditions.

- Testing Environment: Ensure that testing setups mimic real vehicle conditions as closely as possible to obtain reliable results.

With a clear understanding of the test results and their implications, let’s explore some recommendations for intercooler maintenance and improvement.

5. Recommendations for Intercooler Maintenance and Improvement

Regular Maintenance Tips

Routine Cleaning

- Use Cleaning Products: Products like Revive can help maintain intercooler efficiency by removing accumulated oil and debris. Follow the manufacturer’s instructions for application to ensure effective cleaning.

- Check for Blockages: Regularly inspect the intercooler for any signs of blockages or damage that could impair its performance. A clean and unobstructed intercooler ensures optimal airflow and cooling efficiency.

Monitor Performance

- Temperature Monitoring: Install temperature probes to continuously monitor the temperatures of the air entering and exiting the intercooler. Regular checks can help identify performance issues early.

- Performance Data Logging: Use data logging tools to track performance metrics over time. This can provide valuable insights into the long-term effectiveness of your intercooler.

Upgrading Intercoolers

Choosing the Right Intercooler

- Front Mount Intercoolers: For improved cooling capacity and performance, consider upgrading to a front mount intercooler. This type offers better airflow and cooling efficiency due to its placement at the front of the vehicle.

- Air to Water and Water to Air Intercoolers: Depending on your vehicle’s setup and performance needs, you might opt for air to water intercoolersor water to air intercoolers. These offer enhanced cooling in different configurations, with air to water being compact and water to air providing high efficiency.

- Twin Turbo Intercoolers: For vehicles with twin turbos, a twin turbo intercooleris essential to handle the increased airflow and temperature. Ensure the intercooler is compatible with your specific turbo setup.

Installation Considerations

- Proper Fitment: Ensure that the intercooler you choose fits well with your vehicle’s existing components. Proper fitment is crucial for maintaining performance and avoiding issues during installation.

- Professional Installation: Consider having the intercooler installed by a professional to ensure it is set up correctly and performs optimally.

Enhancing Intercooler Efficiency

Improving Airflow

- Upgrade Air Ducts: Improve airflow to the intercooler by upgrading air ducts or adding additional vents. Better airflow helps the intercooler cool the air more effectively.

- Optimize Placement: Ensure the intercooler is placed in a location that maximizes exposure to cooling airflow. For front mount intercoolers, this means ensuring it is unobstructed by other components.

Considerations for High-Performance Applications

- Larger Cores: For high-performance applications, consider intercoolers with larger cores and better cooling efficiency. A thicker core can provide more cooling capacity and support higher boost levels.

- Advanced Designs: Look for intercoolers with advanced designs, such as those featuring internal air diverters or enhanced fin patterns, to improve heat dissipation and performance.

Having covered maintenance and upgrade recommendations, let’s now turn our attention to related resources and further reading.

6. Related Resources and References

Recommended Intercooler Products

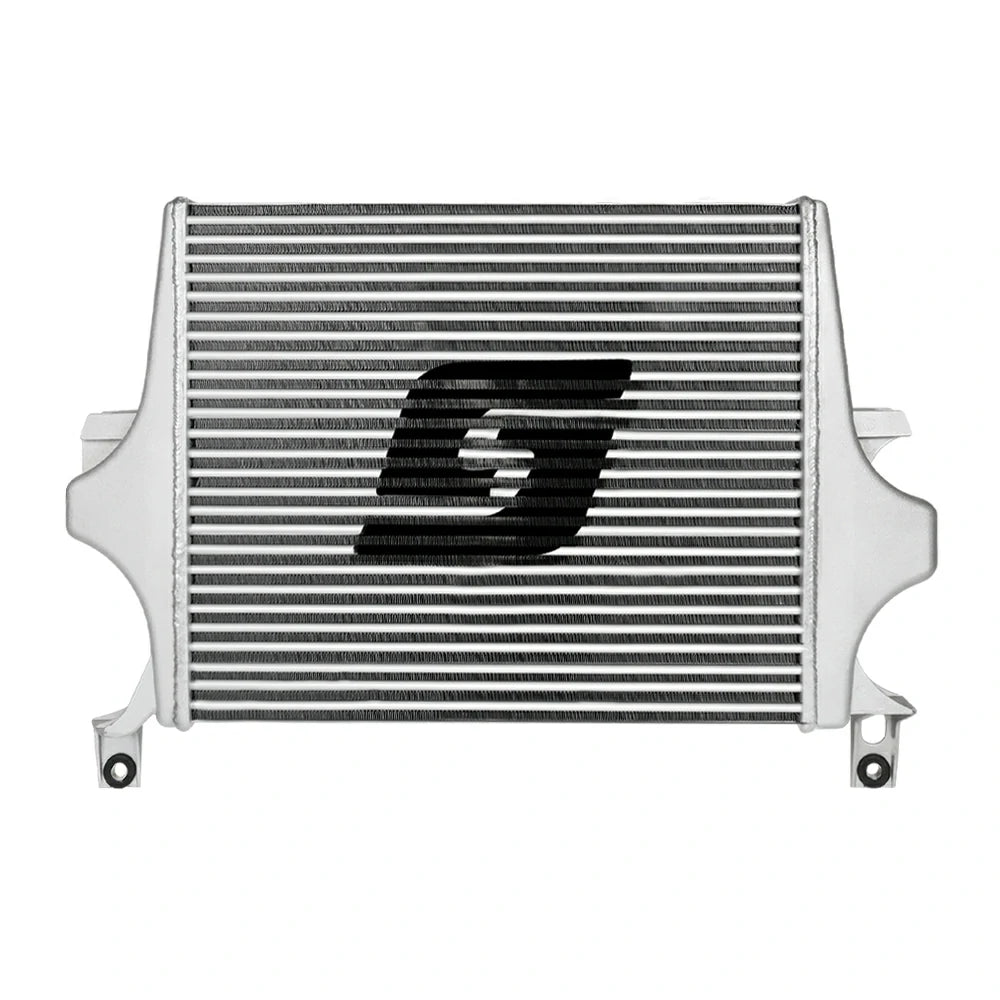

SPELAB Intercooler for Ford Super Duty 6.0L Powerstroke

Intercooler 2003-2007 Ford Super Duty 6.0L Powerstroke V8 F250/F350/F450/F550 | SPELAB

Bolt-on installation for the 2003-2007 Ford 6.0L Powerstroke

Fitment:

2003-2007 Ford F-250 Super Duty (6.0L Powerstroke)

2003-2007 Ford F-350 Super Duty (6.0L Powerstroke)

2003-2007 Ford F-450 Super Duty (6.0L Powerstroke)

2003-2007 Ford F-550 Super Duty (6.0L Powerstroke)

2003-2005 Ford Excursion (6.0L Powerstroke)

Product Overview:

- Brand:SPELAB

- SKU:SPCS08703

- Type:Tube-and-fin intercooler

- Color:Silver

- Application:2003-2007 Ford F-250, F-350, F-450, F-550 Super Duty, and 2003-2005 Ford Excursion (6.0L Powerstroke)

Features:

- Bolt-on Installation:Direct replacement for stock intercoolers.

- Core Design:Tube-and-fin core that is 33% thicker than stock, providing improved cooling efficiency.

- Cast-Aluminum End Tanks:Durable and resistant to cracking, offering better pressure tolerance compared to stock plastic tanks.

- Air Diverter:Internal air diverter in the hot-side end tank ensures even airflow distribution, enhancing heat transfer.

- Powder-Coated Finish:Durable black powder-coated finish for added longevity and aesthetic appeal.

Benefits:

- Improved Efficiency:The thicker core and advanced design contribute to better cooling performance, reducing turbo stress and improving spool.

- Enhanced Durability:Cast-aluminum end tanks and a robust construction increase reliability and lifespan.

- Cost-Effective Upgrade:Provides a significant performance boost at a reasonable price.

If you're looking for an affordable and durable upgrade for your stock 2003-2007 Ford 6.0L Powerstroke, looks no further than this SPELAB cast end tank replacement intercooler.

Our new tube-and-fin intercooler does precisely that. This intercooler combines the proven durability of cast-aluminum end tanks from our premium unit with a lightweight, efficient, tube-and-fin core. While the tube-and-fin core makes this intercooler a cost-conscious option, we haven't sacrificed performance.

The core of this intercooler is 33-percent thicker than stock to provide improved efficiency for lightly modified trucks. Our hot-side end tank also includes an internal air-diverter to ensure even distribution of airflow across the entire core for optimum heat transfer.

Finally, the improved flow reduces stress on the 6.0L turbocharger, leading to a longer lifespan and improved spool. To further bolster durability, this cast end tank replacement 6.0L Powerstroke intercooler is finished in a durable black powder-coat and includes our signature SPELAB Lifetime Warranty.

Conclusion

By leveraging the testing methods and recommendations outlined, you can significantly enhance the efficiency and performance of your intercooler. Whether you are maintaining your current setup or considering an upgrade, staying informed and utilizing quality products will ensure optimal results.

Interested in more detailed product reviews or technical guides? Explore the additional resources listed to deepen your understanding and make informed decisions for your vehicle.

FAQs

Q1: What is the purpose and advantage of an intercooler?

A1: An intercooler’s primary purpose is to cool the air compressed by a turbocharger or supercharger before it enters the engine. This cooling process reduces the air temperature, increasing its density and improving engine performance by allowing more air (and thus more fuel) to enter the combustion chamber. The advantages include increased power output, better fuel efficiency, and reduced engine knock.

Q2: How does an intercooler affect engine power output?

A2: An intercooler improves engine power output by lowering the intake air temperature, which increases air density. Cooler, denser air allows for a more efficient combustion process, leading to higher power output and improved engine performance.

Q3: Is it better to have an intercooler or not?

A3: Having an intercooler is generally better, especially in turbocharged or supercharged engines. It helps prevent excessive heat buildup, reduces the risk of engine knock, and enhances overall engine efficiency and performance. Without an intercooler, the engine may suffer from reduced power and potential overheating issues.

Q4: Are there different types of intercoolers?

A4: Yes, there are several types of intercoolers, including air-to-air, water-to-air, and air-to-water intercoolers. Each type has different cooling mechanisms and is suited to various applications and performance needs.

Q5: Why is an air-to-air intercooler generally more effective than a water-based intercooler?

A5: An air-to-air intercooler is often more effective because it uses ambient air to cool the intake air, which can be more efficient in dissipating heat compared to water-based systems. Air-to-air intercoolers are generally simpler and lighter, making them suitable for high-performance applications where airflow is abundant.

Q6: What are the relative advantages of air-cooled versus water-cooled intercoolers, and which is best for my use?

A6: Air-cooled intercoolers (air-to-air) are typically simpler and lighter, suitable for applications with ample airflow. Water-cooled intercoolers (water-to-air) offer more consistent cooling, making them ideal for applications where space is limited or where maintaining lower temperatures is critical. The best choice depends on your vehicle’s performance goals and application.

Q7: What factors should be considered when configuring an intercooler?

A7: Key factors include the type of intercooler (air-to-air, water-to-air), core size and design, installation location, and compatibility with existing components. It’s essential to consider the intended application, performance goals, and available space.

Q8: Does the style of the intercooler core affect cooling efficiency?

A8: Yes, the style of the intercooler core can impact cooling efficiency. Tube-and-fin cores are common and effective, while bar-and-plate designs offer higher cooling capacity but may be bulkier. Each design has its advantages, so the choice depends on your performance needs and vehicle setup.

Q9: How can intercooler efficiency be improved?

A9: Intercooler efficiency can be improved by upgrading to a higher-quality core, ensuring proper airflow, and regularly maintaining the intercooler. Additionally, using products like Revive to clean the intercooler and optimize its performance can also help.

Q10: What are common failure modes for intercoolers, and how can they be prevented?

A10: Common failure modes include leaks, corrosion, and blockages. To prevent these issues, ensure proper installation, regularly inspect the intercooler for damage or leaks, and use protective coatings to prevent corrosion. Regular maintenance and timely repairs are crucial for extending the lifespan of your intercooler.